How We Make Our Furniture (And Why That Matters)

At Simple Vans, we design modular furniture kits for people who want their van to feel like a home – without spending half their life building it. We’re not flashy. We’re not trying to reinvent minimalism. Our kits are designed to be practical, solid, and good-looking in a quiet kind of way. Simple lines. Natural materials. No faff. If it doesn’t need to be there, it isn’t. Which brings us to the thing that makes all of this possible – how our furniture is actually made.

Flat-Pack Kits You Can Build Yourself

Every Simple Vans kit arrives flat-packed. Each piece is made from PEFC-certified poplar plywood – strong, lightweight, and sustainable. It's pre-sanded but unfinished, so you can oil it, paint it, or just leave it raw if you like that pale, modern look.

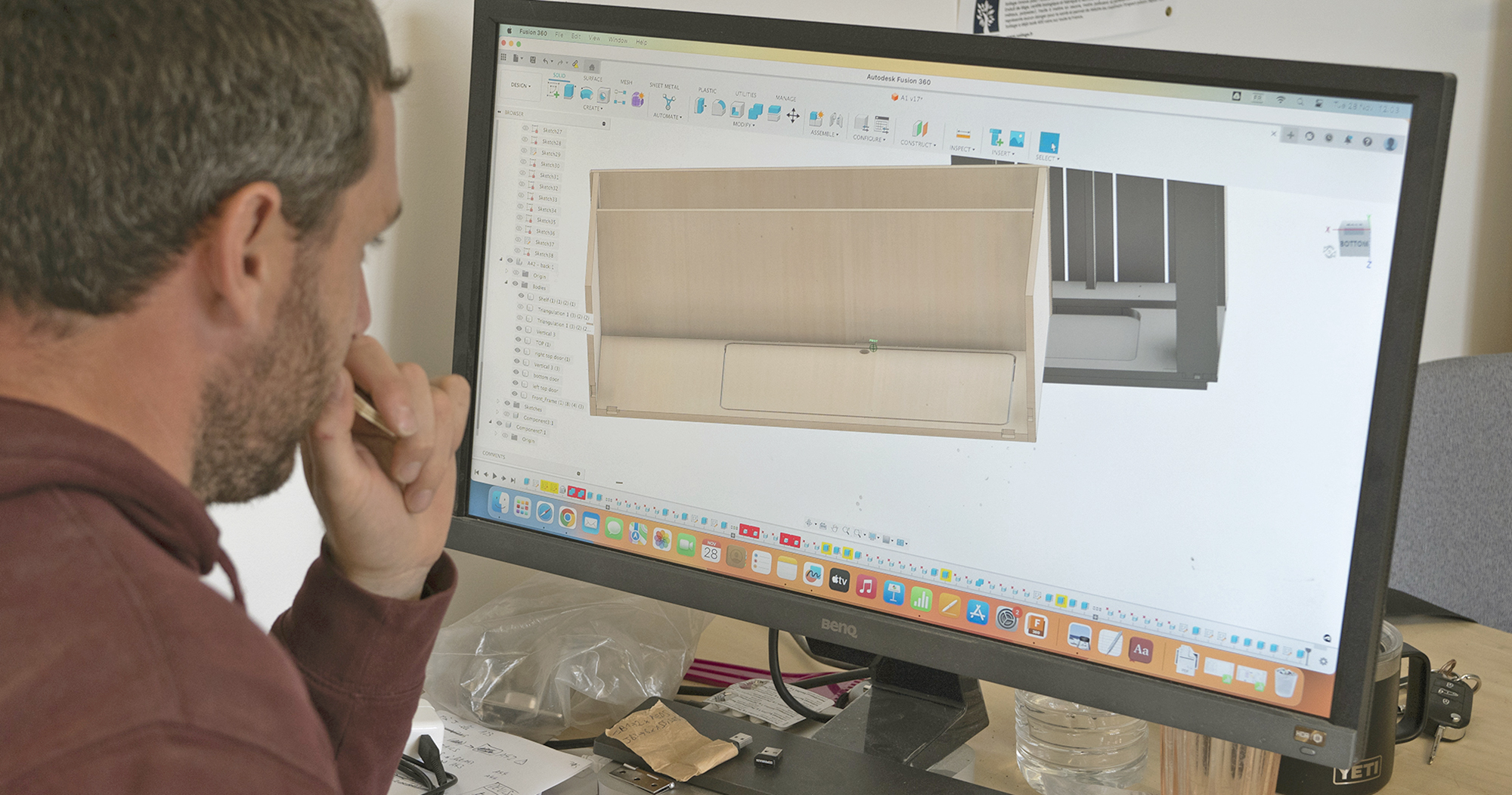

Why CNC? Because Humans Can’t Cut Like This

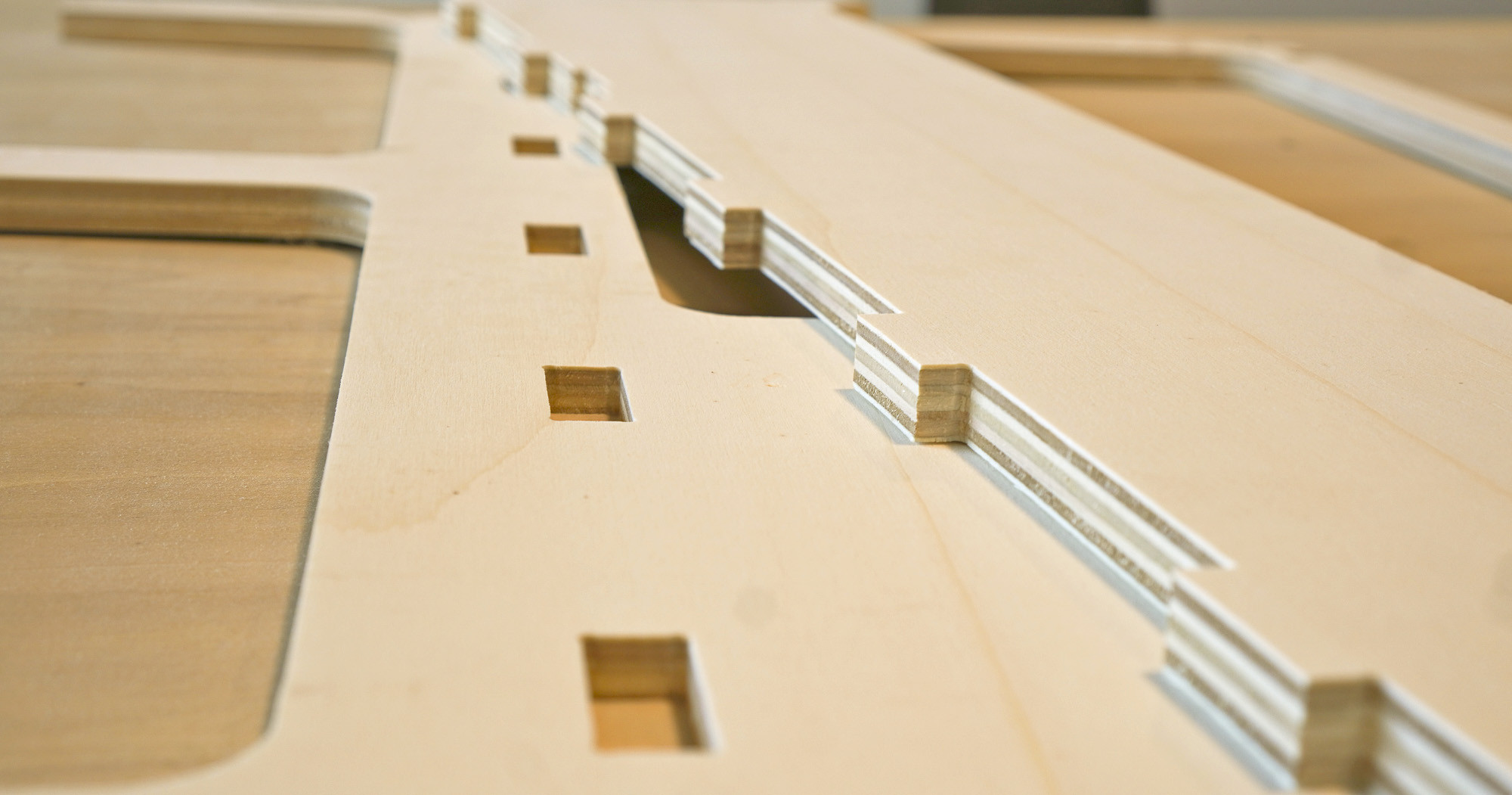

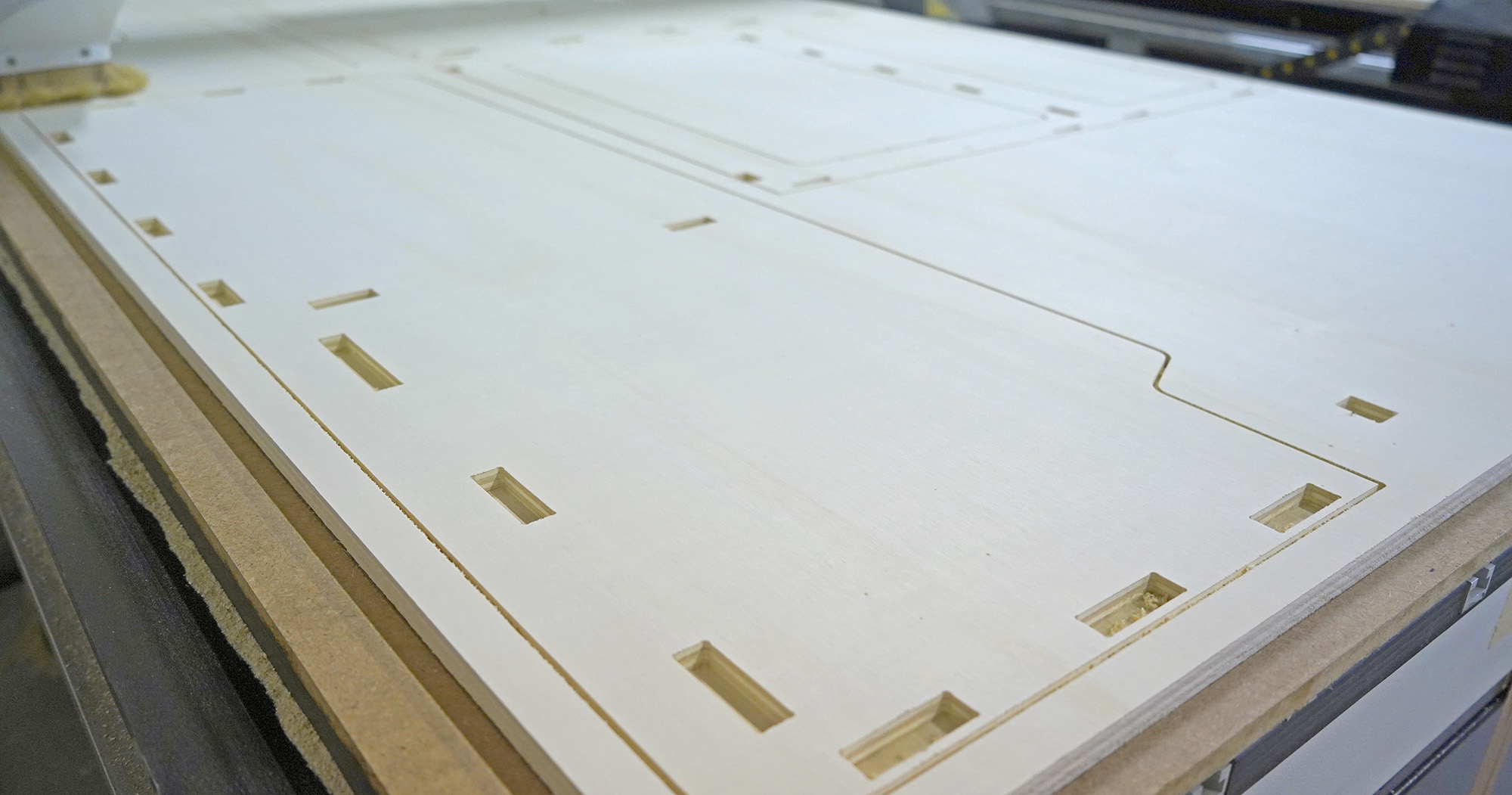

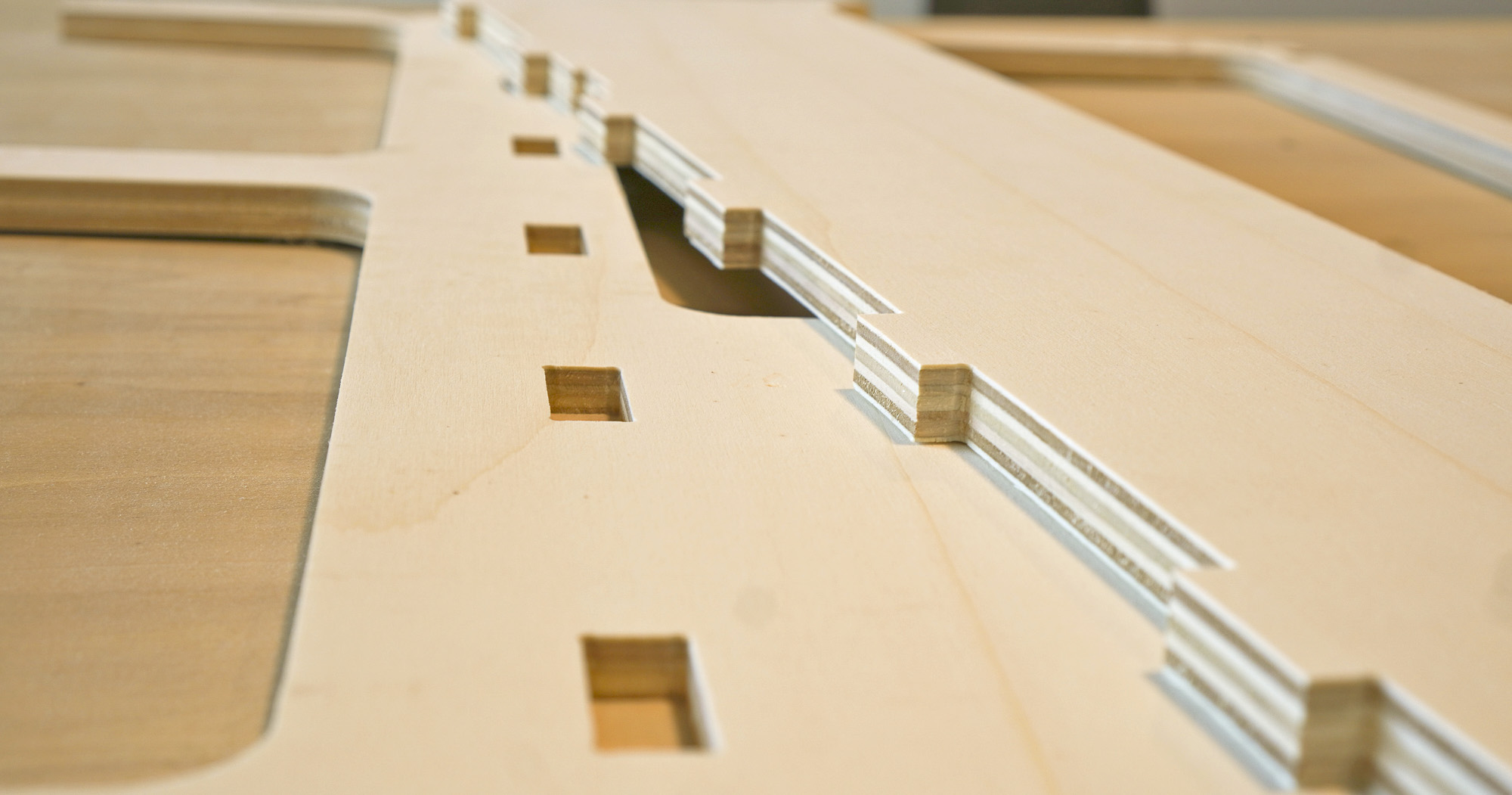

This system only works because we use CNC (Computer Numerical Control) milling to cut every single part. A CNC machine is basically a robot carpenter. It mills the panels with sub-millimetre precision, cutting not just the outside shapes but also the internal slots and locking tabs that hold the furniture together. You could try to copy the outer dimensions with a jigsaw and a hand router – but you’d never be able to replicate the jointing. Even a master carpenter wouldn’t be able to cut these joints by hand in any kind of reasonable timeframe. And definitely not repeatably.

Slots = Strength, Speed, and Sanity

Looks Complicated? It’s Not.

When you open the box, you’ll see a lot of panels with odd little tabs and slots. It might look intimidating at first – but those details are what make the build so forgiving. The panels are designed to fit together one way only. If a piece doesn’t fit, it’s not supposed to go there. That makes it much harder to mess up, even if you’ve never built anything like this before.

We still recommend doing a dry run first – slot everything together without glue, just to make sure it all makes sense. Once you're happy, take it apart, run a bead of wood glue along the edges, and go again. Once you’ve slotted the panels together, we recommend using painter’s tape (the blue kind) to hold the joints snugly together while the glue dries. A quick wipe along the seam with a damp cloth to clean any glue leak, and you’re ready to move onto the next section.

No Visible Screws. No Clunky Hardware.

Another benefit of our slot system? No visible screws. None on the sides, none on the front, none ruining the clean lines of your furniture. Most traditional van furniture relies on metal brackets, screw heads, and fixings that stay visible – especially around corners and joins. Even if it’s strong, it ends up looking messy or a bit improvised.

With our system, all the strength is hidden inside the joints. The result is a clean, uninterrupted surface that actually looks designed – not just assembled.

Stronger Than Screws

Slot and tab joints don’t just look better – they hold up better, too. They distribute load across the entire joint, not just where a screw happens to bite. That means better resistance to twisting, shearing, and general wear and tear – especially important in a moving vehicle where everything’s under constant vibration and motion.

Screws can loosen over time, strip out, or even delaminate the layers around the hole. Slot joints avoid all of that. And once glued, the joint is effectively a bonded structure, not a collection of parts.

One study found that joints like mortice and tenon – which slot and tab construction closely resembles – were 30 to 60 percent stronger under racking and torsion than typical screw-and-dowel joints. So while our kits may look like flat-pack furniture, the structure is in another league.

Less Waste = Better Value

There’s another bonus to CNC cutting: we can nest every part tightly on the plywood sheets, making use of nearly every square centimetre. That means less wood goes to waste – and that efficiency gets passed on to you.

It’s part of why we can offer proper furniture – modular, durable, beautiful – at a price that actually makes sense.

Lighter, Smarter Plywood

We use high-grade poplar plywood sourced for all of our kits. It’s 30% lighter than birch plywood and stronger and harder wearing than MDF – ideal for van interiors where every kilo counts and where humidity can be an issue. We also combine two thicknesses in each kit: 15mm where strength is critical (like bed supports and cabinet walls), and 10mm for drawer fronts, panels, and less structural elements. That means no dead weight, no overbuilding – just a smart balance of durability and efficiency.